Products

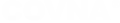

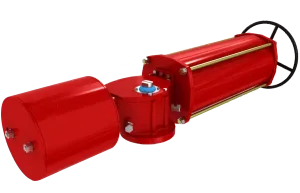

GW Fork Type Pneumatic Actuator for Valves

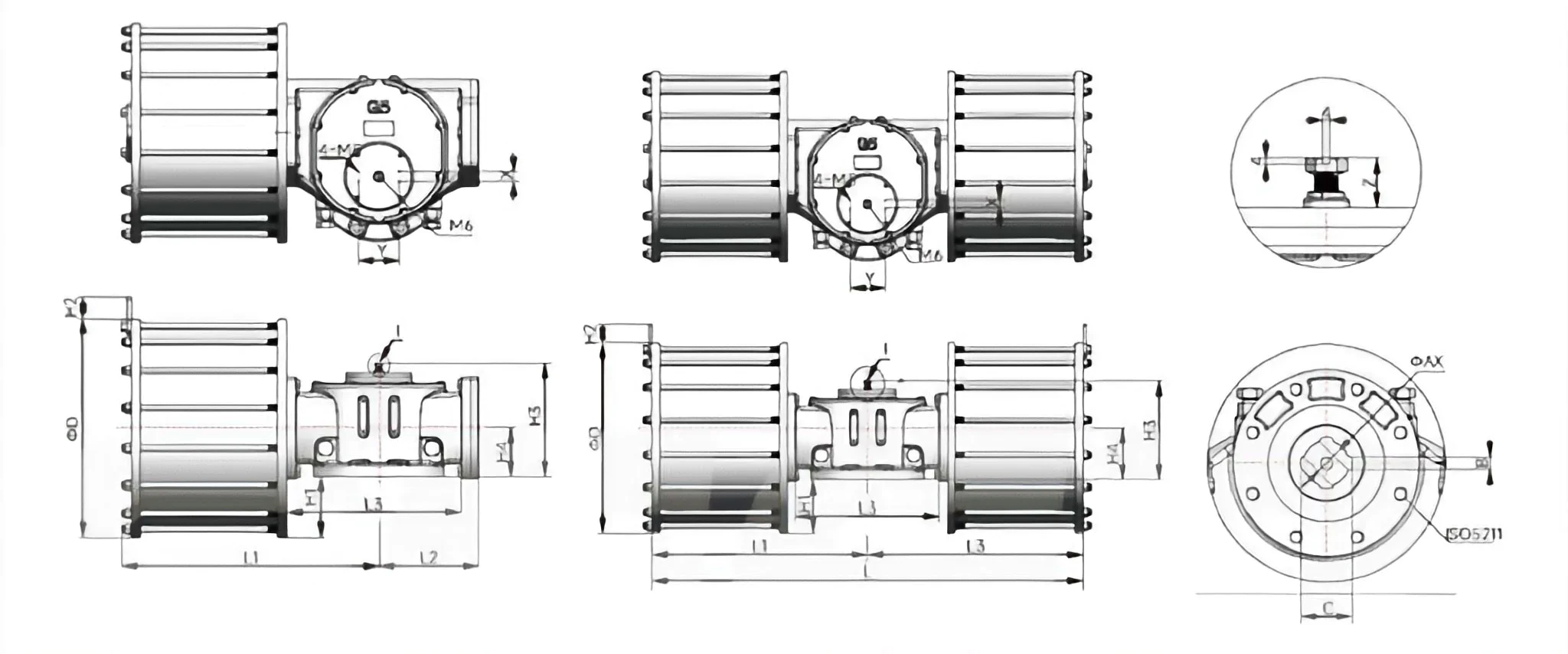

The GW Fork Type Pneumatic Actuator is a heavy-duty, high-performance actuator designed for automating quarter-turn valves (such as ball valves, butterfly valves, and plug valves). It features a fork-type coupling mechanism that ensures precise 90° or 180° rotation with strong torque transmission, making it ideal for industrial valve control applications.

Key Features:

High Torque Output – Provides excellent rotational force for smooth and reliable valve operation.

Robust Construction – Made of high-grade aluminum alloy or stainless steel for durability and corrosion resistance.

Compact & Lightweight – Space-saving design suitable for confined installations.

Double-Acting / Spring-Return Models – Choose between air-to-air operation or fail-safe (auto-close/open) functionality.

ISO 5211 Mounting Standard – Ensures easy and secure attachment to compatible valves.

Long Service Life – Low-friction design reduces wear and maintenance needs.

Technical Specifications (Typical):

Operating Pressure: 0.2~0.8 MPa (2~8 bar)

Rotation Angle: 90° or 180° (adjustable)

Temperature Range: -20°C to +80°C (wider ranges available with special seals)

Protection Rating: IP65 / IP67 (dustproof & water-resistant)

Common Applications:

Oil & Gas – Pipeline isolation and control

Chemical Processing – Handling corrosive fluids

Water Treatment – Flow regulation in pumps and dosing systems

Power Generation – Steam and cooling system valves

Marine & Shipbuilding – Seawater-resistant valve automation

The GW Fork Type Pneumatic Actuator is a cost-effective, reliable, and low-maintenance solution for industries requiring fast, precise, and durable valve automation.

Product Model Description

FOP-G1-P250-SR4-SM-FC-ST

FEIERPU fork pneumatic actuator,G1 type symmetrical fork design single cylinder.Cylinder diameter 250mm,single-acting,spring range 4bar with SM side tie rod manual mechanism.When the air source fails,the valve moves in the closed direction,and the working temperature is normal.

| Example | FOP | G1 | P | 250 | SR | 4 | SM | FC | ST | |||||||

| Enterprise code | FOP | FEIERPU VALVE TECH.CO.,LTD.(enterprise code:FOP) | ||||||||||||||

| G1 | model:G1,G2,G3,G4,G5,G7,G8,G9 | |||||||||||||||

|

|

P | Pneumatic | ||||||||||||||

| H | Hydraulic | |||||||||||||||

| Cylinder Diameter Unit(mm) | 250 | Forexample,a double cylinder is a single diameter*2unit (mm) | ||||||||||||||

|

Form of action |

DA | Double-acting | ||||||||||||||

| SR | Single-acting with spring retum | |||||||||||||||

| Spring Range | 3 | spring Range:3bar | ||||||||||||||

| 4 | Spring Range:4bar | |||||||||||||||

| 5 | Spring Range:5bar | |||||||||||||||

| 6 | Spring Range:6bar | |||||||||||||||

| Manual parts | N | without manual | ||||||||||||||

| SM1 | Side tie rod stressed | |||||||||||||||

| BGM | Bevel gear manual | |||||||||||||||

| WGM | Worm gear manual | |||||||||||||||

| HY | Hydraulic manual | |||||||||||||||

| FC | Fault Off | |||||||||||||||

| FO | Fault On | |||||||||||||||

| FL | Retention | |||||||||||||||

| FLC

FLO |

Trend Off | |||||||||||||||

| Trend On | ||||||||||||||||

| ST | Standard temperature(-20℃ to+80℃) | |||||||||||||||

| LT | Low temperature(-40℃to+80℃) | |||||||||||||||

| HT | High temperature(-20℃ to+150℃) | |||||||||||||||

| HC | High-frequency design | |||||||||||||||

| C | Non-standard design | |||||||||||||||

| If you have any questions,please consult the technical departmentof FEIERPU VALVE TECH.CO.,LTD. | ||||||||||||||||

Product Characteristics

- Shell:The shell is made of ball-milled cast iron to withstand extreme loads.It is sealed with IP67 protection level, and the exposed parts are epoxy-protected surfaces.

- Modular design:It adopts modular design concept,consisting of box module,cylinder module and spring module,which is convenient for on-site configuration and inventory preparation.

- High strength bolted connection:The key position force parts adopt 12.9 grade high- strength bolts,which improve strength and impact resistance,and are more suitable for high-frequency/fast cutting conditions.

- Limit bolt design:The forced release of the fork crankarm and the limit bolt is line (surface)contact,which improves the traditional force point,increases the force area, prolongs the service life,and adjusts the angle±5°.

- Dustproof and waterproof design: The connecting parts of the box,lid and other parts are equipped with high-quality sealing rings,and the protection level reaches IP67,which can continue to work stably in harsh environmental climates.

- Wear-resistant: The combination of well-treated piston rods and guide rods and self-lubricating bearings ensures excellent wear resistance and extends the service life of all sliding parts.

- Safety spring cylinder module: The spring module is welded into a monolithic form after spring compression,which improves the convenience and safety of operation during installation and maintenance.

- Adjustment Range: Two independent stroke adjustments allow for easy± precise 6°adjustment of the switching position.

- Standard connection size: The size of the bottom and valve connection flange complies with ISO5211 standard.

- Anti-corrosion:FOP series pneumatic actuators are sprayed with multiple layers of protective coatings to meet various environmental requirements,and the inner surface of the cylinder is plated with hard chrome to increase corrosion protection and self-lubrication.

- High transmission efficiency:The finely ground piston rod,guide rod and self-lubricating bearing ensure maximum transfer of input power to the valve,greatly improving transmission efficiency and minimizing radial load on the piston rod.

- Application Range:FOP series pneumatic actuators are suitable for switching and adjusting ball valves, butterfly valves,plug valves, and can also be applied to other 90°rotary mechanisms.

- Automated Control Schemes: Feierpu valve tech.has many years of experience in control,and can design various air connection solutions according to customer needs to escort customers.

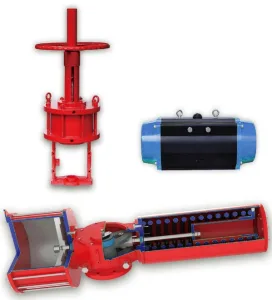

PRODUCT STRUCTURES

| NO. | Name | Material | NO. | Name | Material |

| 1 | Body | Ductile lron | 10 | Spring Seat | Carbon steel |

| 2 | Bearing | PTFE Metal+PTFE | 11 | Nut | 2H |

| 3 | Adjust Stud | Alloy Steel | 12 | Carbon steel | |

| 4 | N u t | 2H | 13 | O - Ring | NBR |

| 5 | Yoke | Ductile Iron | 14 | Nut | Carbon steel |

| 6 | Spring Case | Carbon steel | 15 | Cylinder | Carbon steel |

| 7 | Bearing | PTFE Metal+PTFE | 16 | Carbon steel | |

| 8 | Spring | Alloy Steel | 17 | Nut | 2H |

| 9 | SPring rod | Alloy Steel | 18 | Guide Ring | PTFE |

| NO. | Name | Material | NO. | Name | Material |

| 19 | O-Ring | NBR | 28 | BOlt | 2H |

| 20 | Screw | Carbon steel | 29 | Body Cap | Ductile lIron |

| 21 | O-Ring | NBR | 30 | Cover | Ductile lIron |

| 22 | Piston | Carbon steel | 31 | Drive Shaft | Alloy Steel |

| 23 | Center Bar | Alloy Steel | 32 | Pin | Alloy Steel |

| 24 | O-Ring | NBR | 33 | Roller | |

| 25 | BOlt | 2H | 34 | Guide Block | Ductile lIron |

| 26 | Bearing | PTFE Metal+PTFE | 35 | Bolt | 2H |

| 27 | BOlt | 2H | 36 | Cover Plate | Carbon steel |

Please move to product details.