How to Choose the Right Pneumatic Valve for HVAC and Chemical Plant Applications

Covna Industrial Pneumatic Ball Valve (316 Stainless Steel) for High-Pressure Pipelines

Covna’s 316 stainless steel pneumatic ball valve is engineered to excel in high-pressure industrial pipelines, making it ideal for oil and gas, chemical processing, and power generation applications. The valve features a trunnion-mounted ball design that minimizes friction and ensures tight sealing even at pressures up to 1000 PSI, preventing leaks and reducing energy loss. Its pneumatic actuator, powered by compressed air, enables rapid quarter-turn operation (0-90 degrees) for quick flow modulation, while the anti-blowout stem design enhances safety in hazardous environments. The 316 stainless steel body and ball resist corrosion from harsh media like acids, salts, and hydrocarbons, ensuring a service life of 10+ years with minimal maintenance. Compatible with NPT, flange, and weld end connections, this valve integrates seamlessly with existing systems, supported by Covna’s global technical support and 2-year warranty.

Covna Pneumatic Butterfly Valve with EPDM Seat for HVAC & Water Treatment

Designed for precision flow control in HVAC systems and water treatment plants, Covna’s pneumatic butterfly valve combines affordability with reliable performance. The valve’s ductile iron body and 304 stainless steel disc offer durability, while the EPDM seat provides bubble-tight sealing to prevent leakage—critical for maintaining water pressure and energy efficiency. Its compact, lightweight design simplifies installation in tight spaces, making it ideal for retrofits. The pneumatic actuator, paired with a positioner, allows for smooth modulation (0-90 degrees) and remote control via PLC or SCADA systems, reducing manual labor costs. Suitable for temperatures ranging from -10°C to 120°C, this valve meets ISO 5211 standards and comes with optional accessories like limit switches for real-time position monitoring.

Covna High-Temperature Pneumatic Globe Valve for Steam & Thermal Fluid Systems

Covna’s high-temperature pneumatic globe valve is built to handle extreme thermal conditions, making it a top choice for steam boilers, thermal fluid systems, and industrial heating applications. Constructed with a cast steel body and Inconel trim, the valve withstands temperatures up to 450°C and pressures up to 600 PSI, resisting oxidation and thermal fatigue. Its linear flow control design allows for precise adjustment of flow rates, ensuring stable temperature regulation in processes like food sterilization and chemical synthesis. The pneumatic actuator features a spring-return mechanism for fail-safe operation (opens or closes on air loss), enhancing system safety. Equipped with a handwheel for manual override, this valve is easy to maintain and compatible with industry-standard actuators, backed by Covna’s expert engineering support.

Covna Sanitary Pneumatic Diaphragm Valve for Food & Pharmaceutical Processing

Meeting strict hygiene standards for food, beverage, and pharmaceutical industries, Covna’s sanitary pneumatic diaphragm valve ensures contamination-free fluid control. The valve’s 316L stainless steel body features a smooth, crevice-free design (Ra ≤ 0.8μm) that eliminates bacterial buildup, complying with FDA, 3-A, and EHEDG regulations. Its PTFE diaphragm acts as a barrier between the fluid and actuator, preventing cross-contamination and simplifying cleaning (CIP/SIP compatible). The pneumatic actuator provides gentle, precise operation, avoiding product shear—ideal for handling sensitive media like syrups, vaccines, and dairy products. Available with tri-clamp or weld connections, this valve offers quick disassembly for diaphragm replacement, reducing downtime. Covna’s sanitary valves undergo rigorous testing to ensure reliability in critical, hygiene-focused environments.

We Have The Best Solutions for Your Business

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

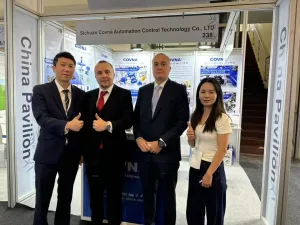

Why Choose COVNA

Professional ProductioTechnology

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

Professional ProductioTechnology

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

Professional ProductioTechnology

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

Professional ProductioTechnology

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

FREQUENTLY ASKED QUESTION

Do You Have Any Question?

To choose the right Covna pneumatic valve, consider key factors like media type (liquid, gas, corrosive, sanitary), pressure range (operating and maximum pressure), temperature, flow rate, and connection type (flange, threaded, sanitary). For example, use 316 stainless steel valves for corrosive chemicals, sanitary diaphragm valves for food/pharma, and high-temperature globe valves for steam systems. Covna’s technical team can also assist with sizing calculations and custom configurations based on your system requirements.

Regular maintenance ensures optimal performance. For most Covna pneumatic valves, this includes inspecting the actuator for air leaks, cleaning or replacing filters in the air supply line, lubricating moving parts (if applicable), and checking seals/gaskets for wear. Sanitary valves should undergo CIP/SIP cycles as per industry standards. Covna provides detailed maintenance guides, and replacement parts (diaphragms, seats, actuators) are readily available to minimize downtime.

Yes. Covna offers pneumatic valves with explosion-proof actuators certified to ATEX, IECEx, and UL standards, making them safe for use in zones with flammable gases, vapors, or dust (e.g., oil refineries, chemical plants). These valves feature sealed enclosures to prevent ignition, and optional intrinsically safe positioners ensure compatibility with hazardous area control systems.

Absolutely. Covna specializes in custom pneumatic valves, offering options like non-standard port sizes, special materials (Hastelloy, Monel), custom actuation speeds, and integrated accessories (solenoids, limit switches, positioners). Whether you need a valve for high-vibration environments, extreme pressures, or unique media compatibility, Covna’s engineering team collaborates with clients to design tailored solutions, supported by prototyping and testing.

Covna pneumatic valves excel in applications requiring fast actuation, high force output, and durability in harsh environments. They operate using compressed air, eliminating the need for electrical wiring in hazardous areas, and are less prone to overheating than electric valves. Electric valves may be preferred for precise proportional control or where compressed air is unavailable, but Covna’s pneumatic valves offer lower maintenance costs, faster response times, and better reliability in high-cycle industrial settings.